Epoxy Resins

We have searched the globe for the

most advanced epoxies ever developed. The 3 dimensional molecular chain of

epoxy offers almost unlimited cross linking potential.

The large

family of epoxy resins represent some of the highest performance resins of

available at this time. Epoxies out-perform all other resin types in terms

of mechanical properties and resistance to environmental degradation, which

leads to their almost exclusive use in aircraft components. As a laminating

resin their increased adhesive properties and resistance to water

degradation make these resins ideal for use in surfboard manufacture. The

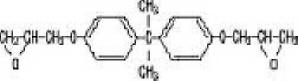

term 'epoxy' refers to a chemical group consisting of an oxygen atom bonded

to two carbon atoms that are already bonded in some way.The figure below

shows the idealised chemical structure of a typical epoxy.

Epoxies

differ from polyester resins in that they are cured by a 'hardener' rather

than a catalyst. The hardener, often an amine, is used to cure the epoxy by

an 'addition reaction' where both materials take place in the chemical

reaction. The chemistry of this reaction means that there are usually two

epoxy sites binding to each amine site. This forms a complex

three-dimensional molecular structure.

Since the

amine molecules 'co-react' with the epoxy molecules in a fixed ratio, it is

essential that the correct mix ratio is obtained between resin and hardener

to ensure that a complete reaction takes place.

Foam

Krypt hand

makes all its own blanks from the finest quality foams and wedge style

cedar stringers, giving our

equipment superior performance and durability.

|

The "Styrofoam" brand name encompasses a wide range of

polystyrene-based foam products. Styrofoam is a product that can be

easily recycled. EPS

(expanded poly- styrene) is the product most people think of

when they hear "Styrofoam". It is white in colour and is

comprised of thousands of individual "beads" which are pressed

together. Although it is not intended for use as

an insulation, it frequently is. Most people have seen cheap

coolers and ice chests made from it. As an insulation, expanded

poly-styrene foam has many qualities which count against it. It

is very hygroscopic (absorbs and holds moisture). This tendency

to get, and stay wet, makes it something to definitely to

avoid.

Styrofoam XPS (extruded poly-styrene) Unlike its expanded cousin ( EPS ) and

virtually all other foams, Styrofoam is completely impervious to

moisture. This is a huge plus. While many other foams start

out as better insulators, they inevitably suffer significant

decline as they absorb moisture from the surrounding air. This

is not the case with Styrofoam SP. Another benefit of its

hydrophobic nature is that no "air gap" is required when

installing it. This means that more insulation can

be packed into a smaller space. If is available in many

thicknesses and two sheet sizes. |

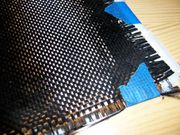

Carbon

Fibre

Carbon

fibre or (alternatively called

graphite fibres,

graphite fibre or carbon graphite) is a material consisting of

extremely thin fibres about 0.005Ė0.010 mm in diameter and composed mostly

of carbon atoms. The carbon atoms are bonded together in microscopic

crystals that are more or less aligned

parallel

to the long axis of the fibre. The crystal alignment makes the fibre

incredibly strong for its size. Several thousand carbon fibres are twisted

together to form a yarn, which may be used by itself or woven into a fabric.Carbon

fibre has many different weave patterns and can be combined with a

plastic resin and

wound or moulded to form

composite materials

such as

carbon fibre reinforced plastic

to provide a high strength-to-weight ratio material. The density of carbon

fibre is also considerably lower than the density of steel, making it ideal

for applications requiring low weight. The properties of carbon fibre such

as high tensile strength, low weight, and low thermal expansion make it very

popular in aerospace, civil engineering, military, and motor sports, along

with other competition sports and marine applications .Itís

high cost is somewhat mitigated by the materialís unsurpassed

strength-to-weight ratio. One major advantage is itís one-fifth the weight

of steel

itís just as strong and stiff,

Carbon Fibre

is now in great demand worldwide to make to make composite components for a

new generation of fuel-saving commercial aircraft and is developing as a

sort of earth conscious material.

parallel

to the long axis of the fibre. The crystal alignment makes the fibre

incredibly strong for its size. Several thousand carbon fibres are twisted

together to form a yarn, which may be used by itself or woven into a fabric.Carbon

fibre has many different weave patterns and can be combined with a

plastic resin and

wound or moulded to form

composite materials

such as

carbon fibre reinforced plastic

to provide a high strength-to-weight ratio material. The density of carbon

fibre is also considerably lower than the density of steel, making it ideal

for applications requiring low weight. The properties of carbon fibre such

as high tensile strength, low weight, and low thermal expansion make it very

popular in aerospace, civil engineering, military, and motor sports, along

with other competition sports and marine applications .Itís

high cost is somewhat mitigated by the materialís unsurpassed

strength-to-weight ratio. One major advantage is itís one-fifth the weight

of steel

itís just as strong and stiff,

Carbon Fibre

is now in great demand worldwide to make to make composite components for a

new generation of fuel-saving commercial aircraft and is developing as a

sort of earth conscious material.

S - Glass

S-Glass Cloth is manufactured

similarly to E-Glass Cloth, but with a different sizing (coating). Thus, S-Glass Cloth is stronger and tougher that E-Glass

Cloth and has 20% greater tensile strength. S-Glass Cloth provides a premium

multi-stage finish and has the highest impact strength of all fibreglass

materials.

sizing (coating). Thus, S-Glass Cloth is stronger and tougher that E-Glass

Cloth and has 20% greater tensile strength. S-Glass Cloth provides a premium

multi-stage finish and has the highest impact strength of all fibreglass

materials.

©Copyright

2009 KRYPT